Baling Press Machine

Engitech Enviro is a leading name of Baling Press Machine Manufacturers, we provide reliable baling press machines designed for durability, efficiency, and long-term performance. Baling Press Machine Manufacturers play a vital role in helping industries compress bulky waste materials into compact, manageable bales that are easy to store, transport, and recycle. From paper mills to warehouses and recycling plants, baling press machines support cleaner operations and cost-effective waste handling.

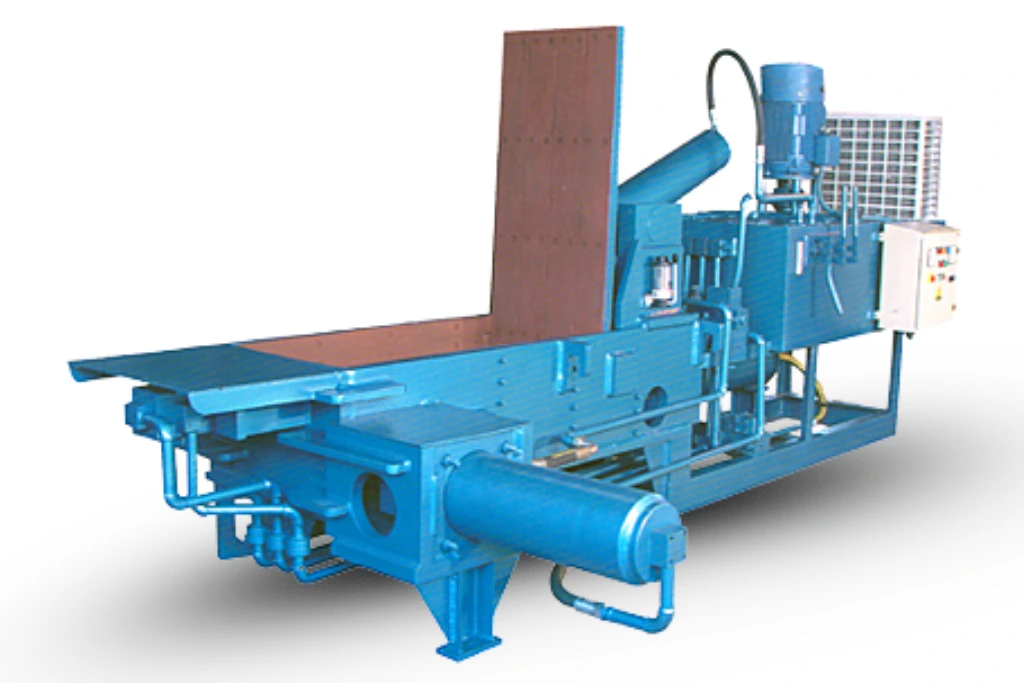

Hydraulic Baling Press Machine

A Hydraulic baling press machine is a mechanical system designed to compress recyclable or waste materials into uniform bales. These machines are available in manual, semi-automatic, and fully automatic configurations depending on operational needs. They are widely used in recycling units, manufacturing plants, and waste processing facilities.

Baling Press Machine Uses

Understanding Baling Press Machine uses helps industries select the right equipment for their operations. Some common uses include:

- Compressing recyclable materials for recycling

- Reducing storage space for waste

- Improving transportation efficiency

- Supporting organized waste segregation

- Enhancing overall plant hygiene

Industries ranging from packaging and printing to logistics and retail rely heavily on baling press machines for daily waste handling.

Importance of Baling Press Machines in Waste Management

Waste materials like paper, cardboard, and plastic occupy large storage areas when left loose. Managing such waste without compaction leads to higher handling costs and operational inefficiencies. Baling press machines solve this issue by compressing waste into compact forms that are easy to stack and transport.

These machines also improve workplace cleanliness, reduce fire hazards, and support environmentally responsible waste disposal practices.

Types of Baling Press Machines

Different industries require different types of baling press machines based on material type and operational scale.

- Vertical Baling Press Machines: Ideal for small to medium waste volumes, vertical balers are compact and cost-effective. They are commonly used in retail stores, warehouses, and small recycling units.

- Horizontal Baling Press Machines: Horizontal balers are suitable for large-scale operations. They offer continuous feeding and higher output capacity, making them ideal for industrial and municipal waste facilities.

- Automatic and Semi-Automatic Balers: These machines reduce manual intervention and improve productivity. Automatic balers are widely used in large recycling plants and waste processing units.

Applications Across Industries

Baling press machines are used across multiple industries, including:

- Recycling plants

- Paper and cardboard manufacturing units

- Warehouses and logistics centers

- Municipal waste processing facilities

- Textile and plastic recycling industries

Their versatility makes them a key component in modern waste management systems.

Baling Press Machine for Waste Paper

One of the most common applications is the Baling Press Machine for waste paper. Paper waste is generated in large volumes by offices, printing presses, packaging units, and paper mills. Loose paper is difficult to store and transport efficiently.

A baling press machine compresses waste paper into tightly packed bales, making it easier to transport to recycling facilities. These bales maintain uniform shape and density, which improves handling efficiency and resale value.

Baling press machines are an essential tool for efficient waste handling, recycling, and space optimization. Understanding Baling Press Machine uses and choosing the right Baling Press Machine for waste paper or other materials can significantly improve operational efficiency. Engitech Enviro offers durable, high-performance hydraulic baling press machines designed to meet the evolving needs of recycling and waste management industries. Investing in the right baling solution today helps businesses operate cleaner, safer, and more sustainably in the long run.