Ballistic Separator

Engitech Enviro is a recognized name in the waste management and recycling industry, developing reliable and efficient separation technologies. The Ballistic Separator plays a vital role in modern waste processing plants. We designed to improve sorting accuracy and recycling efficiency, this machine is widely used in municipal solid waste, dry waste, and industrial recycling facilities.

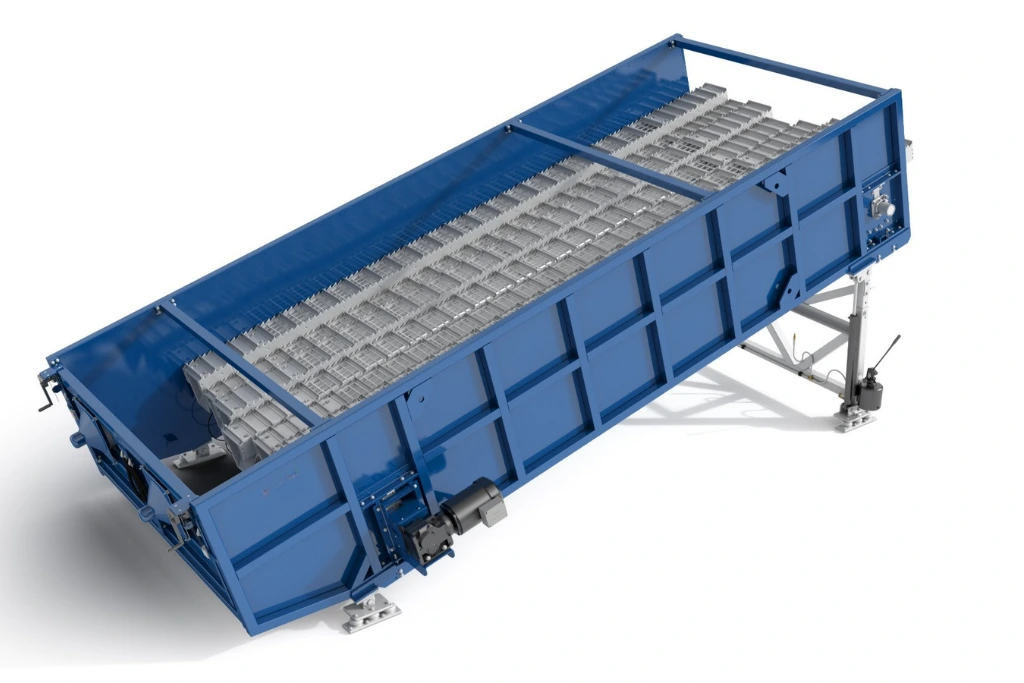

A ballistic separator is a Waste Sorting Machines used mainly in waste processing and recycling plants. The machine uses a series of inclined paddles or plates that move in a specific motion to separate waste streams effectively. The process is crucial in ballistic separator recycling, where clean and accurate separation directly impacts recycling efficiency.

Ballistic Separator Manufacturers

Choosing the right ballistic separator manufacturer is essential for long-term plant performance. Engitech Enviro is a reliable manufacturer that ensures that the machine is built with high-quality materials, good engineering, and industry-compliant safety standards.

Engitech Enviro stands out as a trusted ballistic separator manufacturer by focusing on:

- Robust machine construction

- Custom designs based on plant capacity

- Energy-efficient operation

- Easy maintenance and service support

Our machines are suitable for a wide range of applications, from municipal solid waste plants to commercial and industrial recycling facilities.

Ballistic Separator Working Principle

The ballistic separator working principle is based on the different movement characteristics of waste materials.

When mixed waste is fed onto the machine:

- The paddles move in an oscillating motion.

- Flat materials move upward due to the vibration and angle.

- Rolling or 3D materials move downward as they roll back.

Engitech Enviro provides machines smooth operation, accurate separation, and long service life.

Benefits of Ballistic Separator Machine

- High Separation Efficiency: The machine can separate multiple waste fractions in a single process, improving overall plant productivity.

- Reduced Manual Labor: Automated separation minimizes dependency on manual sorting, reducing labor costs and health risks.

- Improved Recycling Quality: Cleaner output streams result in higher recycling rates and better-quality recyclable materials.

- Low Maintenance Requirements: Modern ballistic separator machines are designed for continuous operation with minimal downtime.

- Versatile Performance: They handle a wide variety of waste types and compositions without performance loss.

Engitech Enviro machines provide these benefits while ensuring consistent and reliable operation.

Ballistic Separator Price

The ballistic separator price depends on several factors, including:

- Plant capacity and throughput requirements

- Number of separation fractions

- Machine size and design complexity

- Customization and automation level

A high-quality machine from a reliable manufacturer like Engitech Enviro ensures lower operating costs, better durability, and higher return on investment over time.

Why Choose Engitech Enviro ?

Engitech Enviro combines technical expertise with practical industry experience to design advanced waste segregation solutions. As a leading ballistic separator manufacturer, our company focuses on innovation, quality, and customer satisfaction. Our machines provide efficient separation, energy savings, and reliable performance, making them a preferred choice for waste management projects across India.

A ballistic separator is an essential machine in modern recycling and waste processing plants. Ballistic Separator working principle to selecting the right ballistic separator manufacturer, every aspect plays a role in improving recycling efficiency. With advanced designs, competitive ballistic separator price options, and proven performance, Engitech Enviro continues to support sustainable waste management through reliable ballistic separator recycling solutions.